What is Automated Assembly?

Automated assembly systems have various types of material handling equipment, gauging and inspection, palletizing, material removal, vision, marking, pressing, dispensing painting, and washing/drying cells. These robotic assembly lines include all processes required to deliver an assembled and inspected product in a faster, more efficient timeline.

Farewell to the old assembly line: Automation is changing manufacturing processes in the automotive industry 4.0.

What is industry 4.0?

It’s important to gain an understanding of what is meant by ‘the fourth revolution’, or ‘industry 4.0’.

The human race has collectively experienced three industrial revolutions since the 1800s; each revolution has been characterized by an exciting new technology that improved manufacturing and processes for the better. The steam engine, the assembly line, and the computer have each been the catalyst for prior revolutions.

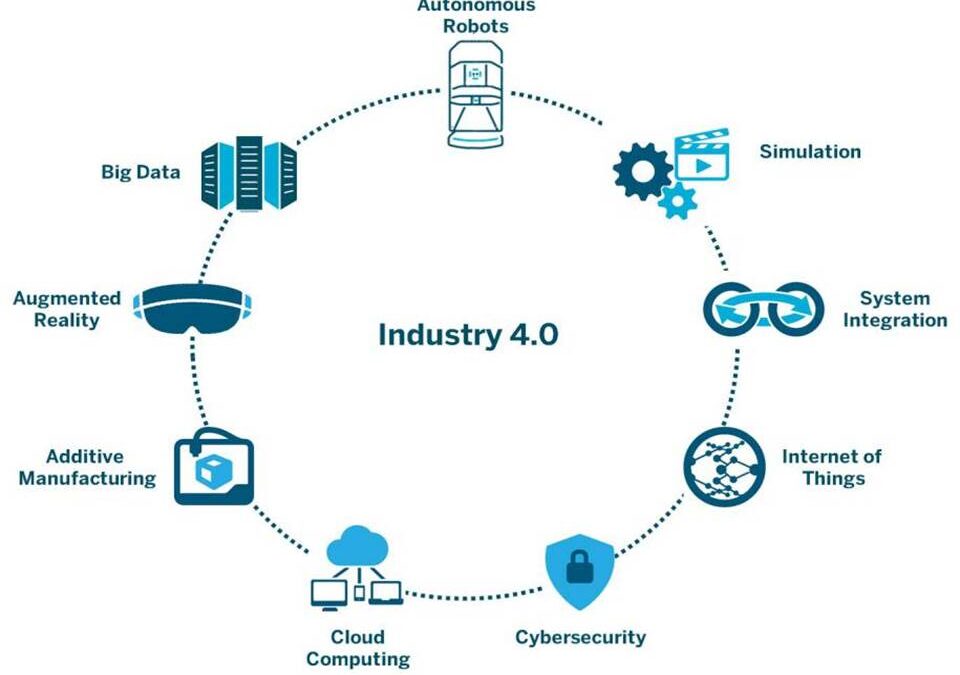

Industry 4.0 refers to the current industrial revolution that we find ourselves in, led by the evolution of robotics, automation, and the internet of things (IoT). Industry 4.0 heralds an age of ‘smart’ systems and digital integration; the name was coined in 2011, and the associated movement is sending ripples through almost every industry around the globe. (4)(5)

Let’s explore some of the ways in which Emerging Industry 4.0 Technologies can positively affect manufacturing and supply chains.

Robotics can improve productivity

Based on current projections, AI is expected to have the ability to increase labour productivity by up to 40% by 2035.

Although some may see robotics and AI as tools to replace human workers, the International Federation of Robotics believes that less than 10% of jobs could be fully automated; robots are generally designed to take on repetitive tasks and allow workers to focus on more intensive duties. (2)(5)

A major benefit of automation in large manufacturing operations is that some tasks could effectively be completed 24/7, thereby boosting production output without any additional labour costs.

Effective robotic completion of some tasks could be especially useful to small business owners. Small businesses generally cannot hire as large a workforce as manufacturing giants; automation may help to level the playing field. (6)(5)

In recent surveys, 57% of employers indicated an interest in boosting performance and productivity through automation and robotics. Some research has shown that increased use of AI in the workplace may actually create new job positions, allowing employers to hire more staff in the future. (2)(5)

Automation can lower overhead costs

Although the initial cost of automated software or robots may be significant, the return on investment can be swift. Business owners might find that some roles are no longer required once AI is being utilized, saving costs immediately.

As an example, some restaurant industry leaders are utilizing delivery robots, which reduces their need for human workers. With fewer employees taking part in hazardous work activities, businesses could also save on health and safety costs, with fewer injuries or time off work for their staff. (6)

Many robots require only a small amount of space to operate, and can safely work alongside humans on assembly lines. The potential reduction in required space means that companies could also downsize to cheaper workplaces and factories.

According to recent surveys, 24% of employers are currently considering automating some roles in order to reduce operating costs. (6)(2)

Smart technology can reduce human error

Human error is a factor that every business must plan for, and time and energy are both spent rectifying the issues when they occur. Particularly when it comes to highly repetitive or mathematical tasks, automation could handle these with a far lower margin of error than human workers.

As automation can be expensive to implement, it’s critical that entrepreneurs take stock of their end-to-end processes, and decide where they can receive the biggest impact from AI.

If your business has significant invoicing operations with a small error margin, this may be a good place to start. If you have an assembly line where small screws are often left out of the finished product, a robot could complete this task effectively for you. (7)

Ensure that you have a solid understanding of your new technology to remain in control during the implementation process.

Final thoughts

The fourth industrial revolution is expected to have far-reaching implications for businesses and people all over the world. If you own a business of any size, it’s worth analyzing your current operations to review where you may have opportunities to utilize automation or robotics.

The future of manufacturing will likely involve humans working seamlessly alongside various artificial intelligence; being prepared for robotic implementation could help to put your business ahead of the competition, and to boost your bottom line.

References

1. “Robotics And Industry 4.0”, Source: https://www.researchgate.net/publication/337605162_Robotics_and_Industry_40

2. “30 Automation Statistics For The New Decade”, Source: https://kommandotech.com/statistics/automation-statistics/

3. “What Is The Fourth Industrial Revolution?”, Source: https://txm.com/what-is-the-fourth-industrial-revolution-industry-4-0/

4. “What Is Industry 4.0”. Source: https://insights.sap.com/what-is-industry-4-0/

5. “The Benefits Of Automation In Today’s Workforce”, Source:

6. “How Robots Cut Costs”, Source: https://www.robotics.org/blog-article.cfm/How-Robots-Cut-Costs/11

7. “How Automation Helps Small Businesses”, Source: https://www.iqvis.com/blog/automation-helps-small-businesses/