Ring Rolling Forging

Ring rolls are the vital components made of a variety of metals with superior strength and durability which forms part of gear assemblies, ball bearings, metal discs, rotors and shafts, drill bits and many other applications in varied industries. Ring rolling forging is the process in which metal rings are made.

How Are Ring Rolls Made?

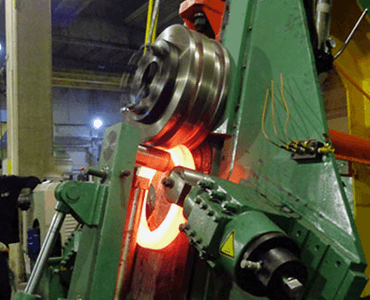

The forming of ring rolls are done by special machinery knows as a ring rolling mill. The mill forms a seamless ring out of blank cylindrical metal or steel billets. The raw material is heated in high temperatures making it malleable and causing it to take the shape of a ring using dies or roller. The rollers gives them shape by rotating in opposite directions. The dies are designed to achieve the desired dimensions of the ring according to its intended application.

Materials Used For Making A Rolled Ring Forging

There are many metal that can be made as a ring roll depending upon the usage of the end product. The most common materials are stainless steel, carbon steel and alloys such as titanium alloys, nickel plated alloys andalloy steel.

Stainless Steel : Stainless steel rolled ring forgings is the most preferred for applications which needs high corrosion resistance and extreme heat resistance. Stainless steel finish also gives a pleasing appearance which increase the aesthetics of the product. There are many grades of steel such as in the three and four hundreds, A182, etc.

Carbon Steel : Carbon steel is another material commonly used for rolled ring forgings. There are low and medium carbon steel which are used for this purpose. They are easily malleable, offers great strength, easy machining and excellent accuracy. The grades are 1010, 1020, 1021, 1022, 1026, 1029, 1030, 1035, 1045 and 1080.

Titanium Alloy :Titanium alloy is also used to make premium rolled ring forgings which are used in various sensitive engineering applications in robotics, space, defence and other uses which requires high performance, high precision and excellent strength to handle varying stress fluctuations.

Alloy Steels: Alloy steels are used for rolled ring forgings that requires corrosion resistance, superior strength, can lasts long with less wear and tear. Steel alloy grades are usually 4340, 4140 and 4130 that are used for making tougher rings made of nickel, chromium, etc.

GNA Gears is a leading manufacturer and supplier of high strength Ring Rolling Forging which are widely used in aerospace, mining, power generation, industrial machineries, oil and gas extraction, construction, automobile and many more. We are the foremost suppliers and exporters of automotive and industrial gears and accessories for over seven decades offering unmatched quality and reliability.