Excellence

Quality

Good

Across Globe

News & Update

Rotavator Gear Box Manufacturers in India

GNA Gears Since 1946Gear manufacturing in India is a fascinating business. While the country is most famous for its software and mobile phone manufacturers, there is an entire industry behind the scenes making the gears and other precision components these companies...

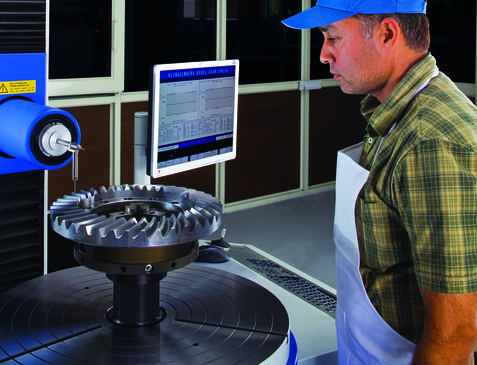

New Klingelnberg C-30 Oerlikon bevel gear cutting machine adds more power to the GNA Gears manufacturing line.

GNA Gears New AdditionGNA Gears Since 1946We are very excited to introduce C-30 OERLIKON BEVEL GEAR CUTTING MACHINE to our production line. GNA Gears motto is precision and as one of the biggest gear manufacture in India we always focus on getting hi-tech and state of...

GNA GEARS ORGANIZED COVID-19 VACCINATION DRIVE

GNA Gears OganizedGNA Gears Since 1946Covid-19 Vaccination DriveWith the second wave of COVID-19 on the rise, Vaccination is the most effective shield against the virus. Prioritizing COVID vaccination for its employees, GNA Gears has started a massive COVID-19...

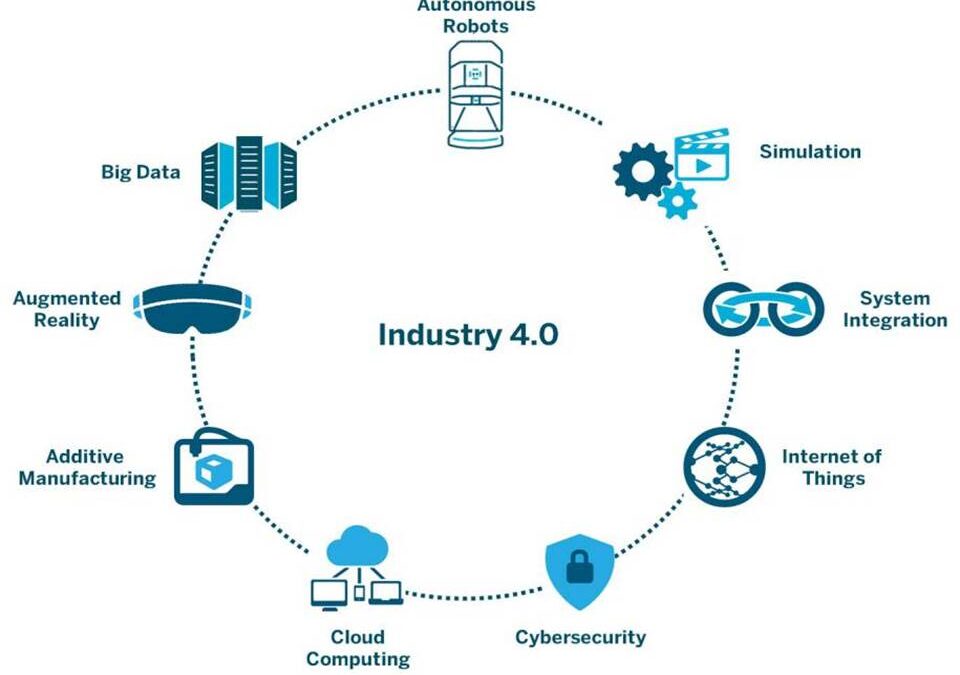

Automated Assembly in Industry 4.0 | GNA Gears

What is Automated Assembly? Automated assembly systems have various types of material handling equipment, gauging and inspection, palletizing, material removal, vision, marking, pressing, dispensing painting, and washing/drying cells. These robotic assembly lines...

Our Manufcturing

Forging

Ring Rolling

Rings rolled precisely & seamlessly in various sizes, shapes and materials for the highest demands.

Upsetters

Our range is 500, 800 & 1200 Ton. Upset Forging with capacity up to 13″ is just one of many forging processes available at GNA Gears.

Drop Hammer

We have 2 Ton Hammer, Belt Type Hammer. Hydro-pneumatic & Pneumatic drop hammers with 4 Tonnes & 5.5 Tonnes capacity respectively.

Dry Cutting – Klingelnberg

Dry Cutting Production Line

With more than 20,000 Sq. Ft of area covered in our facility to produce the precise and top quality crown and tail pinion, Bevel & ring gear with the modern state of the art Klingelnberg Dry Cutting.

Klingelnberg Dry Cutting

Apart from its pioneering use of the latest dry cutting technology in the straight bevel gear sector, it has the further advantage of great flexibility. It achieves high productivity by using cemented carbide tools with correspondingly high cutting speeds.

GNA Gears

GNA is a professionally managed group of auto & transmission component manufacturing companies, catering to worldwide requirements of Automobiles, Tractors, Off-Highway equipment.

Manufacturing

Bevel Gear Manufacture

Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped.

Get Glimpse of GNA Gears