Blogs

From Shaft to Drive: GNA’s Precision Shaft Manufacturing Capabilities

When it comes to drivetrain engineering, gears often steal the spotlight, but it’s the shafts that bear the brunt of torque, speed and alignment. From tractors to turbochargers and commercial axles to planetary gear systems, shafts are the unsung heroes that keep everything in sync.

As industries move toward higher loads, tighter tolerances and smarter gear assemblies, the demand for advanced, reliable and precision-machined shafts has never been greater.

At GNA Gears, we don’t just manufacture shafts; we engineer drivetrain performance. Recognized as one of the most trusted shaft manufacturers in India, we produce a wide spectrum of shafts that seamlessly integrate with our gears, gearboxes and planetary assemblies for OEMs across the globe.

What Makes Shaft Manufacturing So Complex?

Shafts must handle more than just rotation. They must:

- ✔ Transmit high torque over long spans

- ✔ Maintain concentricity at high speeds

- ✔ Resist bending, fatigue and misalignment

- ✔ Fit precisely with gears, splines and housings

Unlike off-the-shelf parts, OEM shafts demand application-specific geometry, metallurgy, heat treatment and machining. From spline profiles to balancing, every micrometer counts.

GNA’s End-to-End Shaft Manufacturing Capabilities

As a vertically integrated gear manufacturing company in India, GNA offers full control over every step of shaft production from raw material to final inspection.

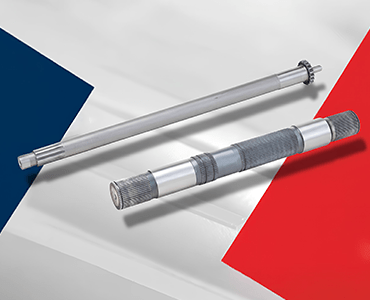

Shaft Types We Manufacture:

- ● Hollow Shafts: Lightweight yet strong, ideal for weight-sensitive designs

- ● Splined Shafts: For torque transmission with perfect fitment in gear hubs

- ● Ground Rotor Shafts: Designed for balance and minimal runout in high-speed systems

- ● Axle & Output Shafts: Built for heavy-load endurance and misalignment resistance

- ● Custom PTO and Intermediate Shafts: Tailored for tractor and off-road vehicles

Technology That Powers Our Shaft Precision

Our facilities house a full suite of technologies purpose-built for shaft production:

- ● Robotic Hammer Forging for uniform grain flow

- ● CNC Turning and Milling for shaft body profiling

- ● Broaching & Cold Spline Rolling for accurate, fatigue-resistant splines

- ● CNC Cylindrical & Rotor Grinding for ultra-low runout and balance

- ● Induction Hardening & Sealed Quench Heat Treatment for wear resistance

By combining forging, machining, heat treatment and inspection under one roof, we eliminate inconsistencies and maintain OEM-level repeatability.

Why Balanced Shafts Matter

An unbalanced shaft can cause:

- ● Gear noise and vibration

- ● Premature bearing wear

- ● Reduced transmission efficiency

- ● Component misalignment and fatigue failure

At GNA, every high-speed shaft (especially rotor shafts) is dynamically balanced and inspected for runout, roundness and alignment so that your drivetrain runs smoothly even at peak RPMs.

Integration with GNA Gear Systems

Our shafts are not standalone parts; they’re part of a complete mechanical ecosystem.

As a manufacturer of planetary gear systems, we make sure that all shafts used in our assemblies are:

- ● Profile-matched to ring and sun gears

- ● Seamlessly splined for fitment

- ● Heat-treated and ground for long service life

- ● Fully inspected for backlash and axial play

This integration makes us not just a component supplier, but a complete solution provider for OEM drivetrain systems.

Trusted by Global OEMs

Whether it's a tractor in Punjab, a loader in Brazil, or an EV gearbox in Europe, GNA shafts are driving machines across continents.

We are among the few shaft manufacturers in India that export to:

- ● USA

- ● France

- ● Italy

- ● Brazil

- ● Sweden

- ● Turkey

- ● UK

Our processes are certified to IATF 16949 and backed by SAP-driven production resulting into quality, consistency and traceability.

One Partner, All Your Shaft Needs

If you’re an OEM looking for shafts that match your gears (not just in rotation but in reliability), GNA Gears is your answer.

From spline shafts to planetary assemblies, we deliver precision, scalability and performance in every component. That’s what makes us a leader among shaft manufacturers in India.

Looking for the right shaft partner? You just found one.

Contact GNA Gears today and let’s engineer something extraordinary.